Project Description

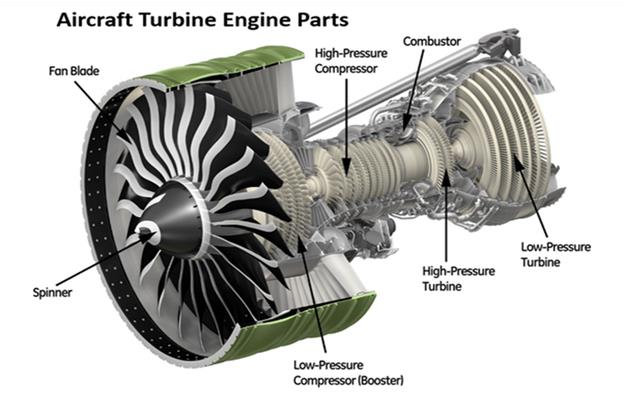

- Developing a solution allowing the analysis of turbine disc that is holding the blades

- Inspection of turbine discs using cameras and artificial intelligence to determine if there are any small cracks or defects that could damage the engine

- Design a system/process to remove human error from this inspection and speed it up as it is a timely procedure

Solution Generation

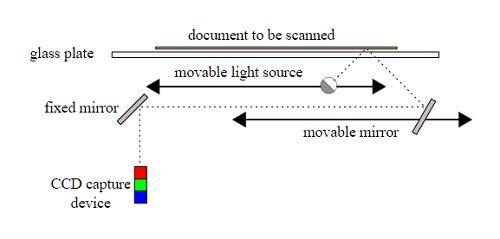

360° Optics

Approach:

Use small, 360-degree camera to capture internal geometry

Explanation:

- Come at the dovetail from the top of flat surface

- Treating dovetail as two separate ‘holes’, combining photos to show entire internal face as one long photo

Pros:

- Easy to operate

- Time efficient

- Produces wrapped and unwrapped images

- High quality resolution

- On-board lighting provided.

Cons:

- Not sure how 360 camera will work with non-circular object

- Little information found online

- Complicated integration with current GE solution

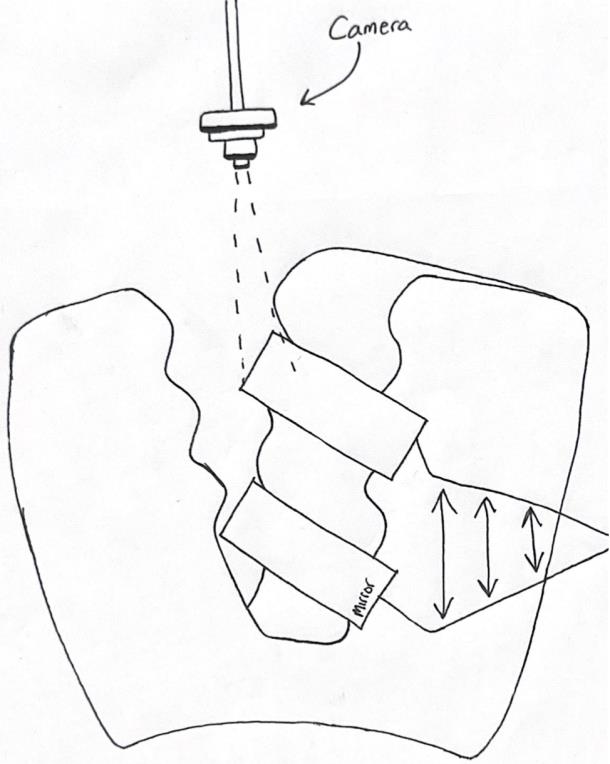

Light Reflection

Approach:

Camera scanning from above dovetail, capturing the full image with the help of mirrors

Explanation:

- Use of line scan camera to first have an overview of the dovetail

- Process would be repeated with use of mirrors to capture hidden parts of the dovetail

- For a 2 notch dovetail we would need 5 passes.

Pros:

- Use of GE line scan camera (no need for miniature, expensive technologies)

- Not expensive

- Precise image location, leading to easier image stitching.

Cons:

- Loss of qualities through mirrors

- Added complexity to create a 2D image (stitching of images through mirror)

- Time consuming

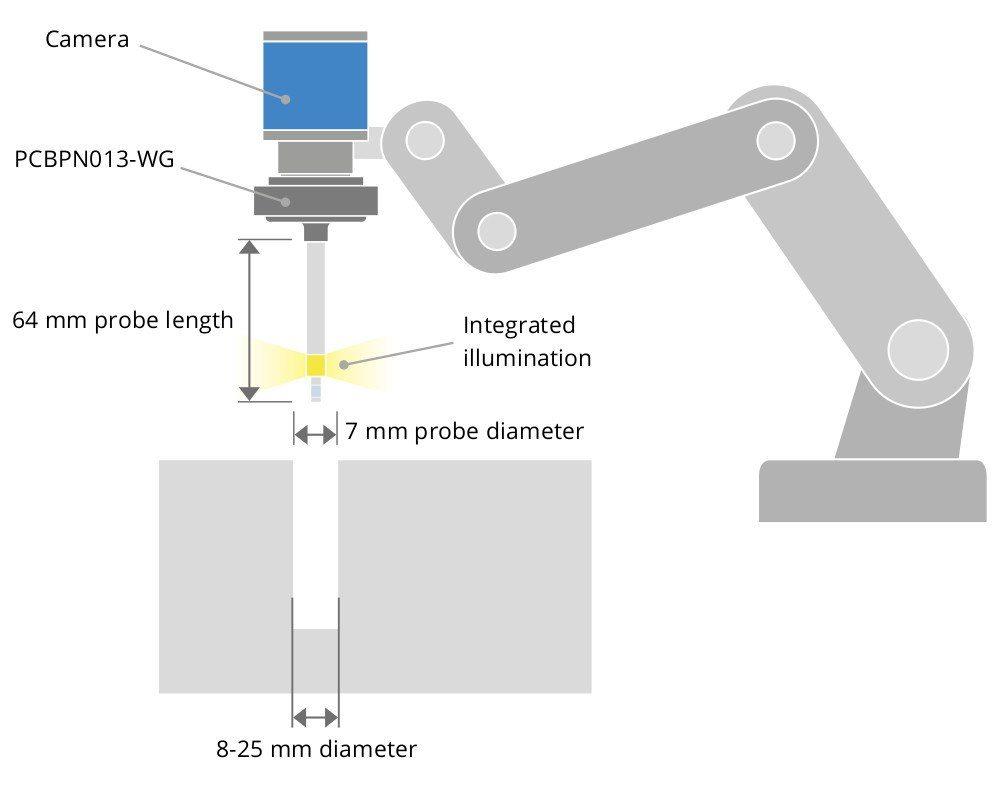

Scanner Method

Approach:

Using a scanner mounted in the robot arm, we can do precious scanning based on the shape of dovetail and generate the grayscale image

Explanation:

- Commercial scanner with a high resolution

- The shape of dovetail is fixed, the robot arm can move along with the surface by pre-programming the route

- Scanning will be continuous, fast, and stable

- Scanner already has built-in white light.

Pros:

- High Resolution

- Live, direct image output

- Built-in White Light

- No image stitching needed

Cons:

- Hard to design

- Require lots of component design

- No experiment supporting

Team Members

Faculty Mentor