Project Description

The group has been tasked with helping BerryGlobal, a manufacturer of plastic products, increase the efficiency of their injection molding process in two ways. First, there are lexan roofs, called dairy covers, over the output of all the injection molders, approximately 30 feet above the ground. Because of this, the dairy covers collect dust and other contaminants floating in the air over time. To clean the tops of these covers, currently production is stopped entirely and boom lifts are used to raise a worker up to clean the tops with a swiffer mop. BerryGlobal is asking the group to provide a portable way to clean the cover from the ground, so that the cleaning process wouldn’t have to stop production. Second, BerryGlobal uses flex link conveyors to transport the plastic products from the injection molder to a printer where the products receive their labels. These printers spew atomized ink into the air and it settles onto the conveyors where it will never dry. This can lead to some products getting ruined if the ink isn’t cleaned regularly. BerryGlobal is asking the group to provide an automatic conveyor cleaner that can be placed within the conveyor line to avoid the ink contamination issue entirely.

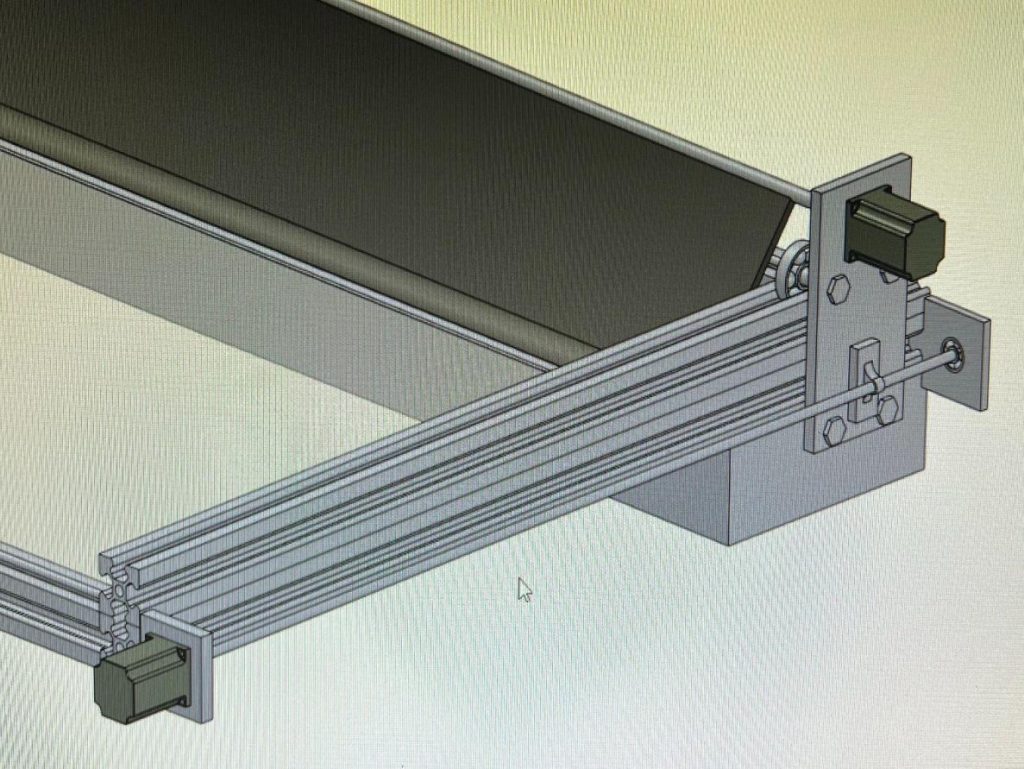

Conveyor Belt

- Contains a nozzle system that sprays Berry Global approved sanitation spray

- Contains a drying component to eliminate moisture after scrubbing

- Is mounted from the ground

Dairy Cover Wiper

- Design must be adjustable for all diary covers sizes

- Must be able to do everyday maintenance without hindering production.

Conveyor Belt Cleaner

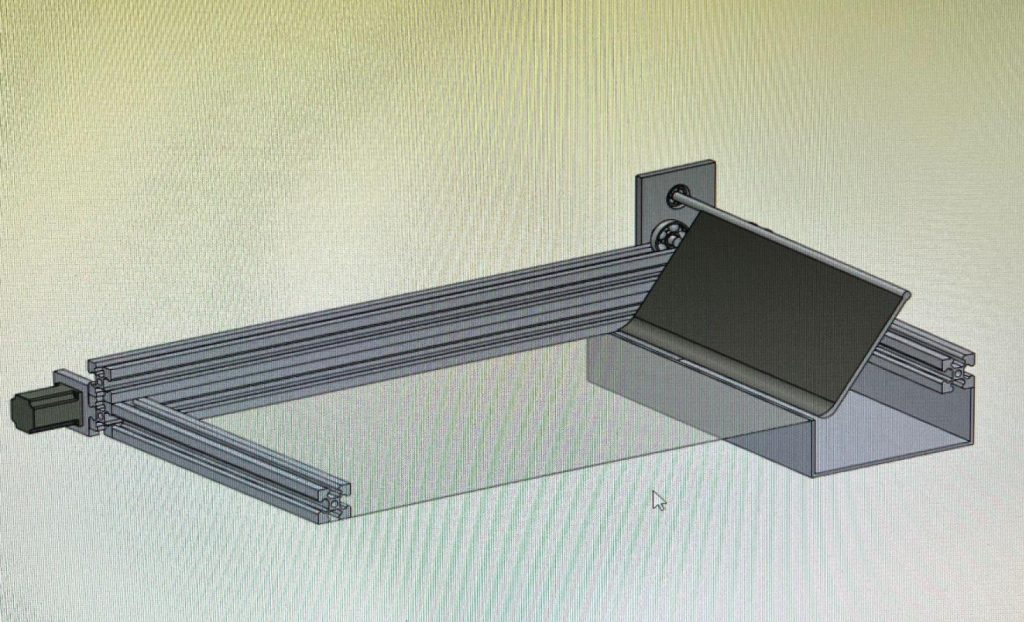

The working solution for the conveyor belt is a 3 stage system similar to a car wash. The first stage is a nozzle that will spray SimpleGreen Extreme, the approved cleaner for BerryGlobal, onto the belt. The second stage will be a foam roller, or other scrubbing device, that will rotate with the belt as it moves. The final stage is a drying stage with the leading idea being a fan to rid the belt of any leftover cleaning solution.

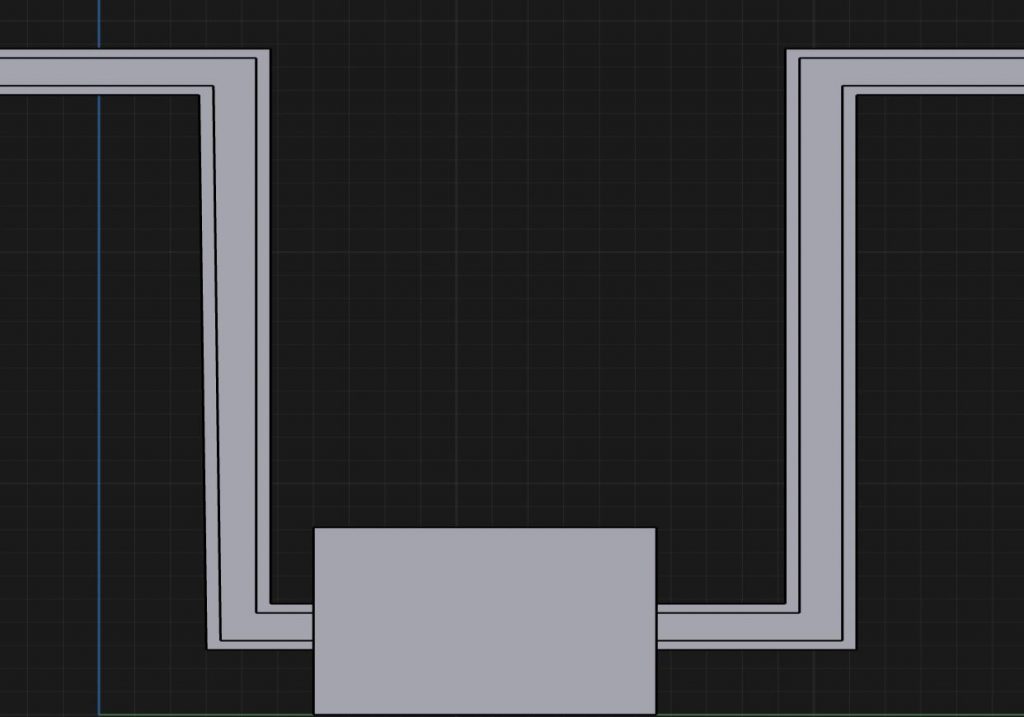

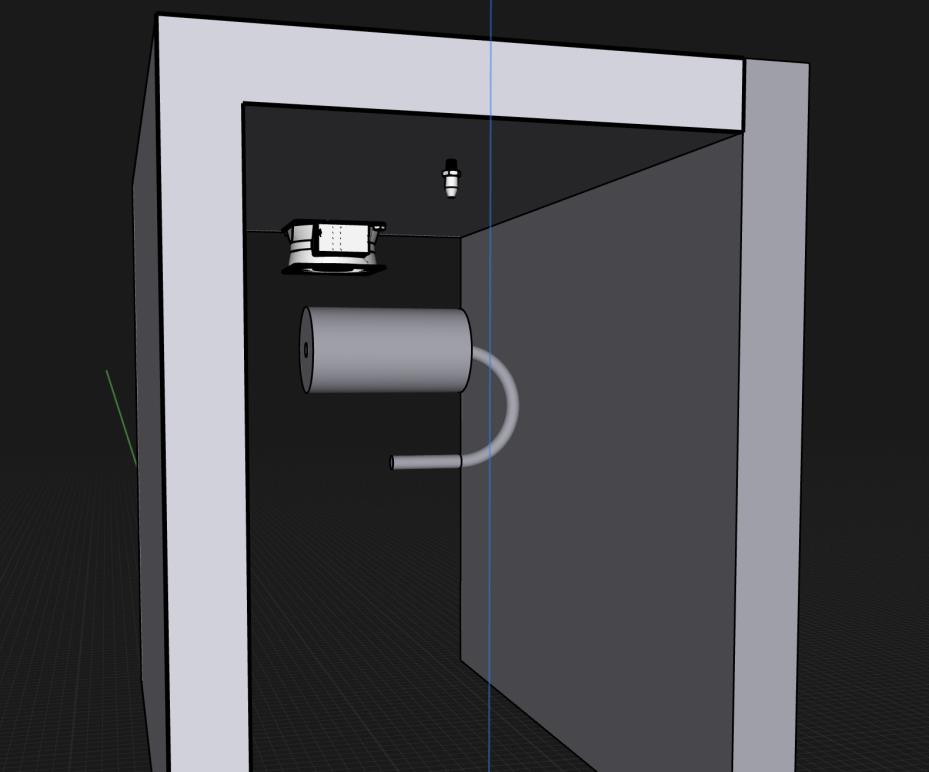

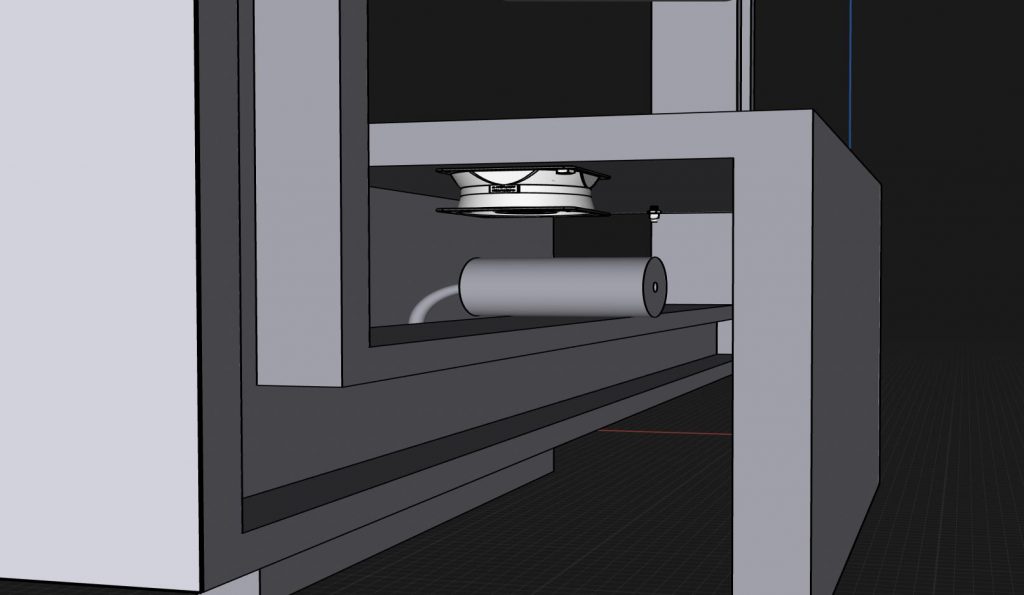

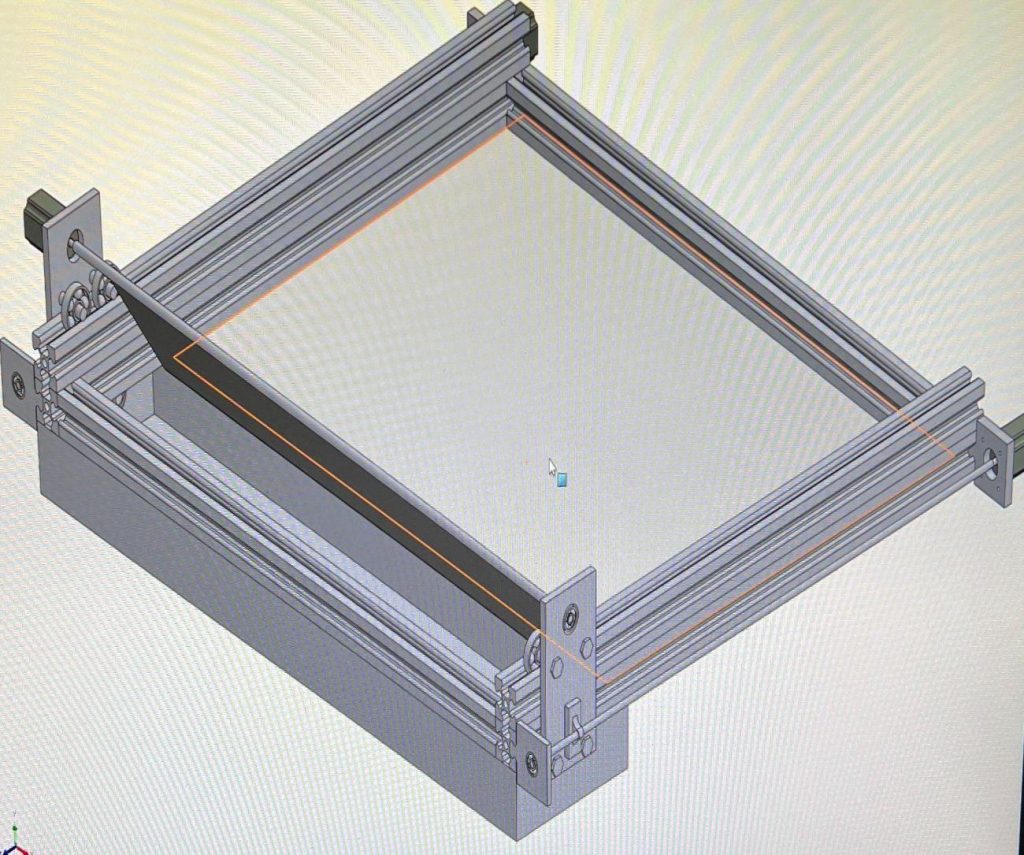

Dairy Cover Cleaner

In this design, the system is attached to the aluminum framework of the dairy covers. Two motors will push a wiper blade to sweep debris into a shoot at the end of the system. This shoot can then be taken out whenever needed to dispose of the debris.

Team members

Faculty Mentor